CONTRACT PROCESSING

Reiko's contract processing

In accordance with the required specifications,we also accept contract processing that only processes such as vapor deposition/Imagining on the supplied base film and coating with the supplied paint.

On course, as a partner in new product development, we can also propose joint development and product planning support.

Reiko, a thin film processing professional, will support your stable product supply and technological innovation.

Consignment flow

Inquiries

Please contact us via our website, email, or phone.

Meeting

Sales and technical staff will visit you directly and accept requests for experiments and prototypes.

Examination of machines used

Back up your development from the beginning.

Evaluation

You will actually evaluate the completed sample.

Prototype of actual machine

We accept a wide range of processes from small lot sample production to mass production.

Contract

We arrange quality control items according to customer's request and undertake quality assurance.

Introduction of processing equipment

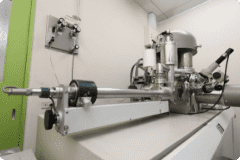

Vacuum deposition machine

A device that heats and evaporates inorganic substances such as metals in a high vacuum (10-4torr) and condenses them on a substrate such as a film to form a thin film.

Specifications

| File thickness | 6~250μm |

|---|---|

| File width | 500~2,100mm |

| Winding diameter | ~1,100mm |

* Thin film deposition machine material

AI [aluminum], Ag [silver], Cu [copper], Cr [chromium], Sn [tin], Ni [nickel], SiO [silicon oxide], ZnS [zinc sulfide]

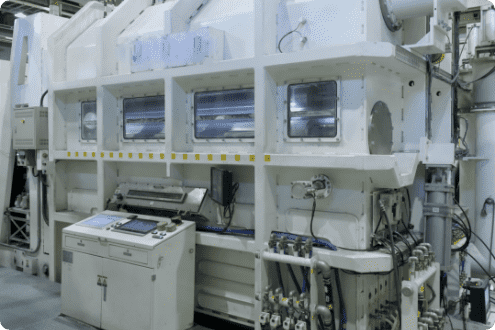

Sputtering machine

It is a device that transports a film substrate by Roll to Roll and spatters a dielectric film, a transparent conductive film such as ITO, and a metal film on the surface of the substrate.

A metal to be attached to a film is set as a target in a vacuum chamber, a gas such as Ar is turned into plasma with the target as a cathode potential, and these gases collide with the target, and the ejected fine particles are deposited on the opposing substrate film.

Specifications

| File thickness | 50~200μm |

|---|---|

| File width | 1250mm (When the base material width is 1340 mm) |

| Winding diameter | ~650mm |

* Spatter machine material

AIN [aluminum nitride], Ag alloy [silver], Cu [copper], NiCr [nichrome], SUS [stainless steel], TiO2 [titanium oxide (IV)], ITO [indium tin oxide], Nb2O5 [niobium oxide (V) )], SiN [Silver Nitride], Al2O3 [Aluminum Oxide]

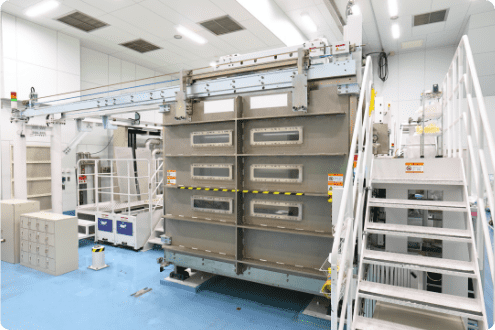

CVD film forming machine

It is a device that transports a film substrate by Roll to Roll and forms a barrier film such as SiOx and an optical film on the surface of the substrate by the plasma CVD method.

A gas such as oxygen is turned into plasma, the supplied raw material gas is chemically reacted by the energy of the plasma, and the product is deposited on the substrate film.

Specifications

| File thickness | 50~200μm |

|---|---|

| File width | 1,100~1,340mm |

| Winding diameter | ~ 650mm |

There are various coating methods such as gravure coat, reverse coat, comma coat, die coat, bar coat, etc. Reiko features a compound technology that combines coating technology with compounding technology that produces functions and characteristics according to the application.

Not only designs such as coloring but also various functions such as physical and chemical resistance, adhesion and mold release performance can be given to various plastic films. In addition, it is equipped with a wide, clean class 100 coater, and is compatible with a wide range of precision fields such as electronic materials.

Coating machine specifications

| File thickness | 6~250μm |

|---|---|

| File width | 500~2,100mm |

| Winding diameter | ~ 800mm |

| Coating method | Gravure, reverse, die, etc. |

| Drying method | Hot air |

| Coating amount | 2~150 g/m2 |

| Other functions | Laminate processing |

| Processing environment (cleanliness) | Class 100※ |

* Some equipment at Hino Factory